Cement

We support our clients in securing the necessary cement supply for their large-scale construction projects worldwide. From initial planning to final delivery, our team ensures a seamless procurement process, offering high-quality cement that meets international standards.

Portland Cement CPA 55 - CEM I 52.5 N

-

Contains a balanced mix of calcium silicates (C₃S and C₂S) for strong early and long-term compressive strength.

Includes aluminum oxide (Al₂O₃) and iron oxide (Fe₂O₃) to improve durability and resistance to chemical aggression.

Chemical Product Composition and Physical-Mechanical Properties are available in the data sheet ⬇️

-

Packaging :

50 Kg Bags

1000 Kg Big Bag

Bulk

M.O.Q :

12 500 MT

-

Government & Public Infrastructure : Roads, bridges, tunnels, and railways.

Commercial Construction : Skyscrapers, business hubs, and complexes.

-

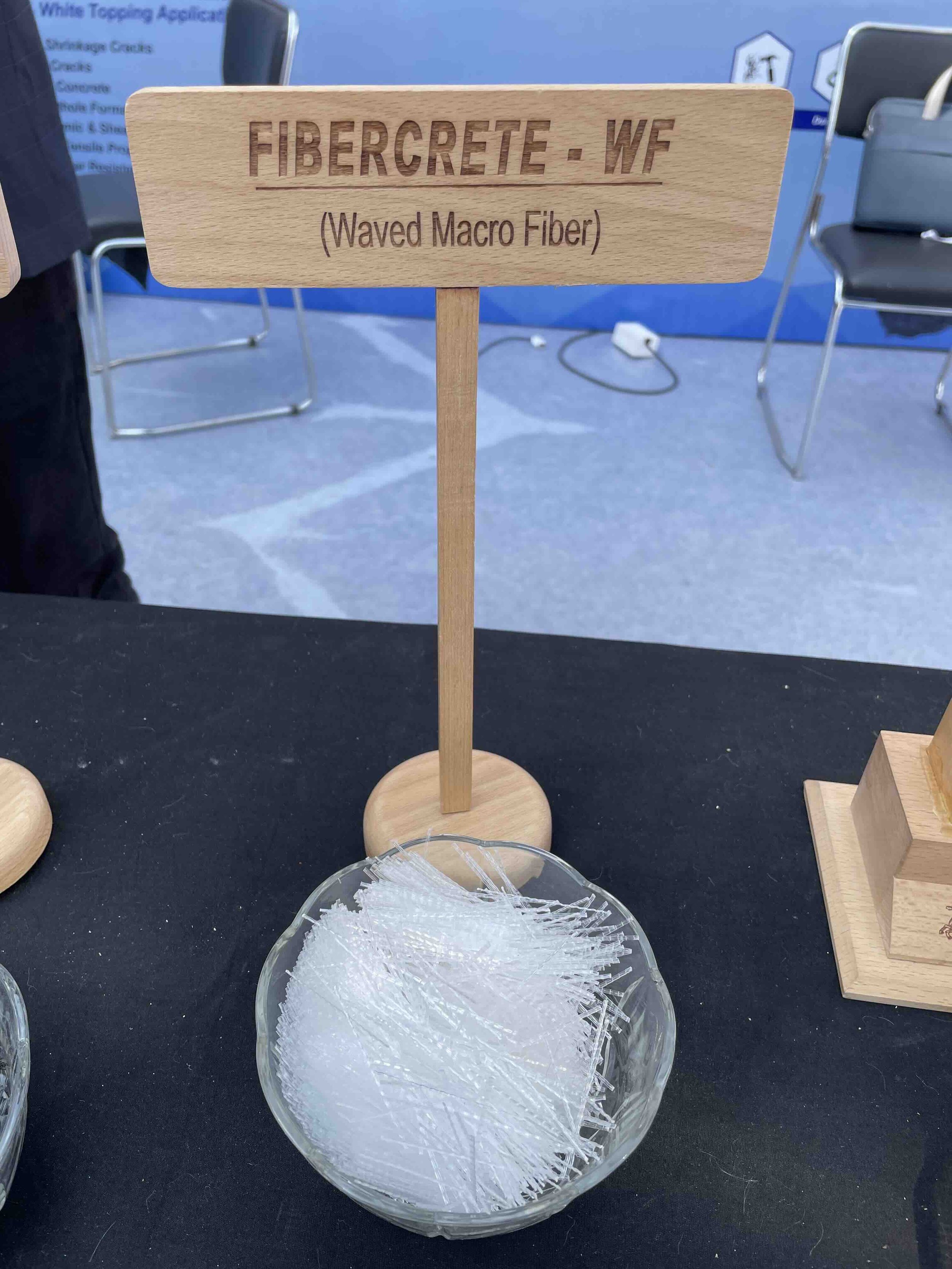

Fibers added to cement improve its mechanical strength, limit cracking, increase durability and can offer specific properties such as thermal insulation or fire resistance, depending on their nature.

Portland Cement - CEM II/A - L 42.5 R

-

Low C₃A (< 3.5%) content ensures high sulfate resistance (SR5).

High levels of CaO support stable and long-lasting hydration.

Very low levels of MgO, alkalis, and chlorides for increased durability.

Chemical Product Composition and Physical-Mechanical Properties are available in the data sheet ⬇️

-

Packaging :

50 Kg Bags

1000 Kg Big Bag

Bulk

M.O.Q :

12 500 MT

-

Government & Public Infrastructure : Roads, bridges, tunnels, and railways.

Commercial Construction : Skyscrapers, business hubs, and complexes.

Port & Marine Engineering : Docks, harbors, and coastal projects.

Dams & Hydroelectric Plants : Water management and renewable energy infrastructure.

-

Fibers added to cement improve its mechanical strength, limit cracking, increase durability and can offer specific properties such as thermal insulation or fire resistance, depending on their nature.

With our extensive production capacity, efficient logistics, and commitment to reliability, we guarantee timely shipments and tailored solutions to meet the specific requirements of infrastructure, government, and mega-scale developments across the globe.

Portland Cement - CEM I 42.5 N-LH/SR5

-

Contains 80–94% Portland clinker, with 6–20% limestone (CaCO₃).

The limestone content improves paste rheology and helps reduce CO₂ footprint.

High calcium silicate (C₃S, C₂S) content supports rapid strength development.

Chemical Product Composition and Physical-Mechanical Properties are available in the data sheet ⬇️

-

Packaging :

50 Kg Bags

1000 Kg Big Bag

Bulk

M.O.Q :

12 500 MT

-

Government & Public Infrastructure : Roads, bridges, tunnels, and railways.

Commercial Construction : Skyscrapers, business hubs, and complexes.

Port & Marine Engineering : Docks, harbors, and coastal projects.

Dams & Hydroelectric Plants : Water management and renewable energy infrastructure.

-

Fibers added to cement improve its mechanical strength, limit cracking, increase durability and can offer specific properties such as thermal insulation or fire resistance, depending on their nature.

What you should know about Concret

What is Concrete?

Concrete is a mixture of cement, sand or fine aggregates, coarse aggregates, water, and admixtures. Cement, sand and coarse aggregates are the major raw materials for concrete, and they need to be precisely proportioned before making concrete to produce a mixture that is strong and long-lasting. Moreover, the proportions of each component added to concrete vary depending on the type of concrete being made, and the components react differently with each other based on this ratio. Workability, strength, durability, creep, shrinkage, etc., are the prime properties of concrete. Now, let’s explore how many types of concrete are available for construction.

Different Types of Concrete Used in Construction.

Normal Strength Concrete

Normal-strength concrete is made by combining the four basic materials - cement, sand, coarse aggregate and water. Its strength ranges from 10 MPa to 40 MPa, which depends on the characteristics of the cement you used and the local weather conditions at the construction site, and its initial setting time is 30 to 90 minutes.

Plain Concrete

A basic concrete mix called plain cement concrete or PCC, consists of cement, water, fine and coarse aggregates, and optional admixtures. PCC has excellent compression strength. However, it is extremely weak in tension because it lacks steel or other reinforcements. PCC mixes are typically designed with a 1:2:4 and 1:3:6 ratio. It is frequently used in the foundation of a building.

Reinforced Concrete

Reinforced concrete, also called reinforced cement concrete, is created using reinforced bars; typically, rebar is used to increase the tensile strength of the concrete. The overall durability of the concrete is increased when its compressive strength and the tensile strength of the reinforcement material are combined. It is mostly suitable for large-scale construction projects requiring high tensile strength, like tall buildings, bridges, dams, or any other structure where a structure must support incredibly heavy loads.

Glass Concrete

Glass concrete is one of the special types of concrete in civil engineering. When recycled glass is added to the concrete as an aggregate or, depending on the desired result, substituted for both fine and coarse aggregates, the mixture is referred to as glass concrete. Glass aggregates can range in size from a fine talc-like powder to gravel-side pieces to six-inch glass rocks, and they are almost always made from recycled glass. Depending on the desired appearance, glass can either be used in chunks when mixed with cement or crushed using a glass crushing machine. Glass concrete is a visually appealing and extremely polished-looking material for countertops, floors, and tiles because it usually has a shiny or "glowing" appearance.

Air-Entrained Concrete

Concrete with tiny air bubbles in it that aid in releasing internal pressure is known as air-entrained concrete. During the mixing process, an air-entraining agent is added, which lowers the surface tension and creates air pockets in the slurry. When there are freeze-thaw conditions- temperature swings from below to above freezing- this type of concrete is appropriate for building environments where there is a build-up of water. Over time, the structure will last longer because the tiny pockets give water room to expand, preventing concrete from cracking and resisting scaling. 5% to 7% of the concrete mix is made up of microscopic air bubbles. Because adding air to concrete reduces its density, more cement is used to compensate for the strength.

Fiber-Reinforced Concrete

A composite material consisting of cement, water, aggregates, and rounded or flat fibers is called fiber-reinforced concrete. Many fiber types, including carbon, asbestos, glass, steel, polypropylene, and organic fibers, are used widely for reducing permeability, bleeding, and the development of small cracks. Fiber-reinforced concrete is widely used in the construction of dams, roads, bridges, runways, walls, aircraft parking areas, pavements, etc.

Portland Cement CPJ 45 - CEM II 42.5 N

-

Composed primarily of calcium silicates (C₃S, C₂S) for high mechanical strength.

High content of calcium oxide (CaO) for rapid hydration and setting.

Low content of magnesium oxide (MgO) and alkalis to improve long-term durability.

Chemical Product Composition and Physical-Mechanical Properties are available in the data sheet ⬇️

-

Packaging :

50 Kg Bags

1000 Kg Big Bag

Bulk

M.O.Q :

12 500 MT

-

Port & Marine Engineering : Docks, harbors, and coastal projects.

Dams & Hydroelectric Plants : Water management and renewable energy infrastructure.

-

Fibers added to cement improve its mechanical strength, limit cracking, increase durability and can offer specific properties such as thermal insulation or fire resistance, depending on their nature.

Lightweight Concrete

As the name suggests, lightweight concrete has a lower density, and it is used to decrease the structure's self-weight. Lightweight aggregates like silica sand, pumice, sawdust, scoria, and volcanic cinder blocks are used to make lightweight concrete. Any type of concrete with a density level of less than 1920 kg/m3 is considered lightweight concrete because the specific aggregates selected are what ultimately determine the density of the finished product. Lightweight concrete is used for walls, flooring, and places where the overall "dead weight" of a building can be decreased to help prevent collapse.

Ready-Mix Concrete

Ready mix concrete is produced in a manufacturing plant and transported to a building site through a truck that is equipped with a mixer. To ensure that the cement is ready to pour at the job site without hardening beforehand, it typically contains admixtures.

Polymer Concrete

Polymer concrete is made by replacing a polymer binder that cures and hardens for the lime and shale-based Portland cement. Examples of polymer binder materials include polyester, epoxy mixtures, vinyl ester, acrylics, and many other types of polymer resins. The type of resin used in the concrete determines the goal of polymer concrete. For example, epoxy binders help reduce shrinkage during curing, while acrylic binders provide weather resistance and faster setting times. Because polymer plastic is more sticky than cement, it can be added to concrete to create a mix with a higher tensile strength than one made only of Portland cement. Because polymer concrete resists corrosion well, it is frequently used in sewer systems, swimming pools, and other constructions that come into direct contact with liquids and chemicals that can cause corrosion.

Pervious Concrete

Pervious concrete is a porous concrete that allows water to seep through to groundwater below. Pervious concrete is used to construct pavements and roads. It can absorb water at a rate of up to five gallons per minute and is made to deal with stormwater accumulation. With little to no fine aggregates, this type of concrete has more space for air and water to flow through and due to that Stormwater can filter through the pervious concrete and seep into the earth.

Self-Compacting Concrete

Self-compacting concrete, one of the special types of concrete in civil engineering, also known as self-consolidating concrete, is a type of concrete that possesses three special characteristics like,

A high filling ability that allows it to easily flow in all directions around confined spaces and obstacles like steel reinforcement when it is poured;

A high passing ability that allows it to pass around these obstacles;

Segregation resistance, or the ability to maintain its original state during transportation, placement, and after placement.

With less labour and a faster concrete placement time, these characteristics allow the concrete to set into the mould very closely without the need for additional support or vibration. Self-compacted concrete is more fluid because it contains more fine aggregate, typically sand, and additives like superplasticizers and viscosity-enhancing admixtures, which make sure the sand particles are evenly distributed. This kind of concrete is made by mixing these additives with the standard ingredients—cement, fine and coarse aggregate, and water—in a concrete mixer.

What you should know about Fibers

What is Fiber Reinforced Concrete?

Glass fibers or other fibrous materials, either natural or synthetic, are added to concrete mixtures to create fibre-reinforced concrete. In other words, it’s composition of cement, sand, aggregates, water and discrete, short fibers distributed evenly throughout the material.

Fibers improve the overall energy absorption and structural integrity of concrete and reduce the risk of cracking. However, fibres are weak in flexural strength- the bending capacity of the concrete without breaking, so they are not a substitute for steel reinforcement concrete.

When blending fiber-reinforced concrete, two factors to consider are the fiber size, also known as the aspect ratio, which is the length of the fiber divided by its diameter, and the water-cement ratio. Since the volume of fibers used in the concrete can affect the strength and durability of the structure, it is also important to consider the percentage of fiber you use in the concrete. Fiber-reinforced concrete should be mixed uniformly without separating the mixtures. In order to prevent fibers from balling together, they must be added before the water is mixed in. This should ideally be done with a laboratory mixer and filtered through a wire mesh basket.

Different Types of Fibers Used in Fiber-Reinforced Concrete.

-

Steel fibers are typically added to concrete to increase its strength and ability to support loads after cracks. Steel fibers for concrete are typically loose or bundled, formed into various geometries- such as crimped, hooked-end, or with other mechanical deformations for anchorage in the concrete—and made of carbon or stainless steel.

-

The main applications for glass fiber-reinforced concrete (GFRC) are in architecture and the modification of cement-based panel structures. Glass fibers can be used in concrete to create lighter, more contemporary, and aesthetically beautiful structures, such as architectural cladding for buildings or furniture.

-

All over the world, natural fibers are utilised in non-commercial applications to strengthen cement-based products. They are made of different natural materials, including sugarcane, coconut, sisal, jute, and other materials, and they have different lengths, shapes, and properties.

-

There are two types of synthetic fibers- micro-fibers and macro-fibers.Micro-fibers, which are often composed of acrylic, polyester, nylon, or polypropylene, among other materials, are used in concrete to minimise shrinkage cracks. However, in concrete structures where high tensile strength is required, macro-fiber is a more affordable reinforcement option than welded wire. Common structures constructed with microfibers added to the mix include sidewalks, curbs, and driveways; common structures constructed with macro-fibers include septic tanks and manholes.

In the construction industry, fiber-reinforced concrete is also known by different names according to the type of fiber used in concrete, such as steel fiber-reinforced concrete, glass fiber concrete, etc.

Benefits of Fiber-Reinforced Concrete.

The following are the benefits of fiber-reinforced concrete:

Fiber-reinforced concrete improves the tensile strength of the concrete.

It improves the durability of the concrete.

It minimises the water and air voids that contribute to the natural porosity of the gel.

Fibres are more resistant to creep; hence, the creep performance of rebars is greatly influenced by the orientation and volume of fibers.

It prevents cracks and increases the static and dynamic properties of the concrete.