Fiber Additives & Fiber Reinforced Concrete

🧩 What is Fiber Reinforced Concrete ?

Fiber Reinforced Concrete (FRC) is a type of concrete that incorporates discrete, short fibers into the mix to enhance its mechanical properties. These fibers are evenly distributed throughout the concrete matrix and serve to control cracking, increase tensile strength, and improve durability.

FRC is increasingly used in modern construction due to its improved resistance to cracking, impact, and shrinkage, offering better long-term performance compared to conventional concrete.

Fiber Composition and Interaction with Concrete

Fiber additives are made from engineered materials designed to complement and reinforce the cement matrix. Depending on their origin and properties, they interact with concrete in different ways to enhance its behavior both in the plastic (fresh) and hardened states.

How Fibers Interact with Concrete ?

📌 In Hardened Concrete :

Once cracks begin to form under stress, fibers bridge the cracks, transferring stress across them.

This improves the post-crack behavior, giving the concrete residual strength after cracking.

Fibers enhance impact resistance, toughness, and fatigue performance.

In some cases (steel, macro-synthetics), they replace or reduce traditional steel mesh reinforcement.

📌 In Fresh Concrete (Plastic State) :

Fibers disperse uniformly during mixing, forming a 3D network.

They limit plastic shrinkage cracking by holding microcracks together as the concrete sets.

Fibers improve cohesion, reducing segregation and bleeding (especially in shotcrete).

🧵 Types of Fiber Additives 🧵

We offer a wide range of fiber additives tailored to various construction needs :

📌 Polypropylene Fibers

Microfibers used for plastic shrinkage crack control.

Improve durability and surface resistance.

Ideal for slabs, screeds, and plaster.

📌 Steel Fibers

Dramatically increase tensile and flexural strength.

Replace or reduce traditional reinforcement.

Suitable for industrial floors, tunnels, precast, and pavements.

📌 Glass Fibers

Alkali-resistant for concrete and cementitious mixes.

Improve crack control and dimensional stability.

Used in architectural panels and thin elements.

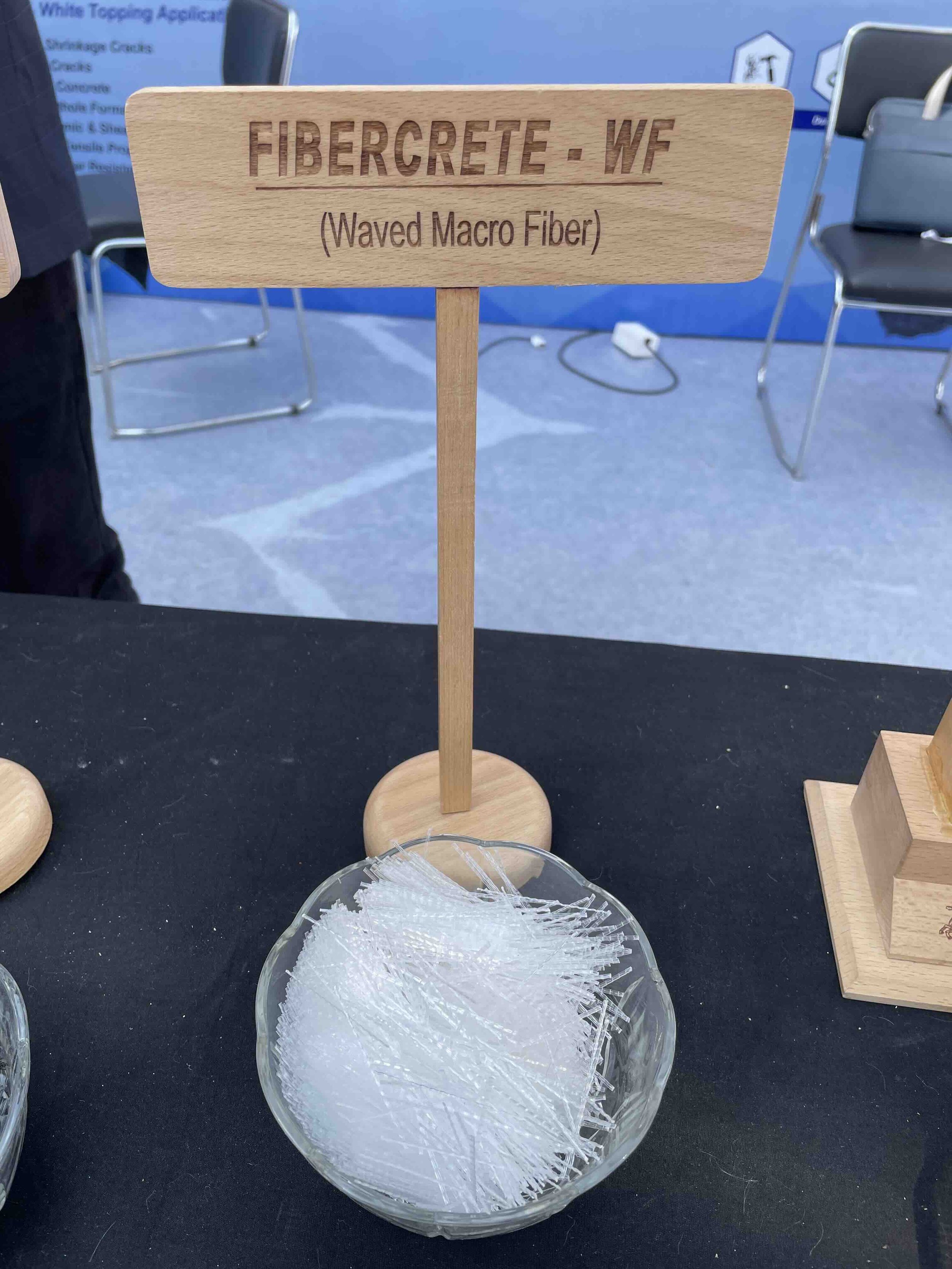

📌 Synthetic Macro Fibers

Structural-grade plastic fibers (e.g., PE, PET).

Improve post-crack performance and impact resistance.

Alternative to mesh or light reinforcement.

⚙️ Why Use Fiber Reinforced Concrete?

Fiber additives bring a range of technical and practical advantages :

Reduces plastic shrinkage and drying shrinkage cracks.

Enhances tensile, flexural, and impact strength.

Speeds up construction timelines by reducing or eliminating steel mesh.

Increases freeze-thaw durability.

Improves abrasion and surface wear resistance.

Suitable for complex shapes and thin elements.

Reduces maintenance costs and improves service life.

🛠️ Applications of Fiber Reinforced Concrete

Fiber-reinforced concrete is widely used in :

Industrial floors and warehouses.

Pavements and exterior slabs.

Tunnels and underground works.

Precast concrete elements.

Shotcrete and sprayed concrete.

Bridges, ports, and marine structures.

Residential slabs and lightweight panels.